CEL was contacted by Reventec Ltd, a manufacturer of sensors which are used by the professional motor racing industry, as well as in other applications which demand high reliability at elevated temperatures and under severe vibration.

Reventec was looking to produce a strain gauge with a 0 to 5V output for measuring the torque applied to the steering column of a racing car. Previously they had been buying in an amplifier from a third party, but it was quite expensive, too large, and required adjustment using a screwdriver which meant it could not be fully encapsulated to protect it from vibration.

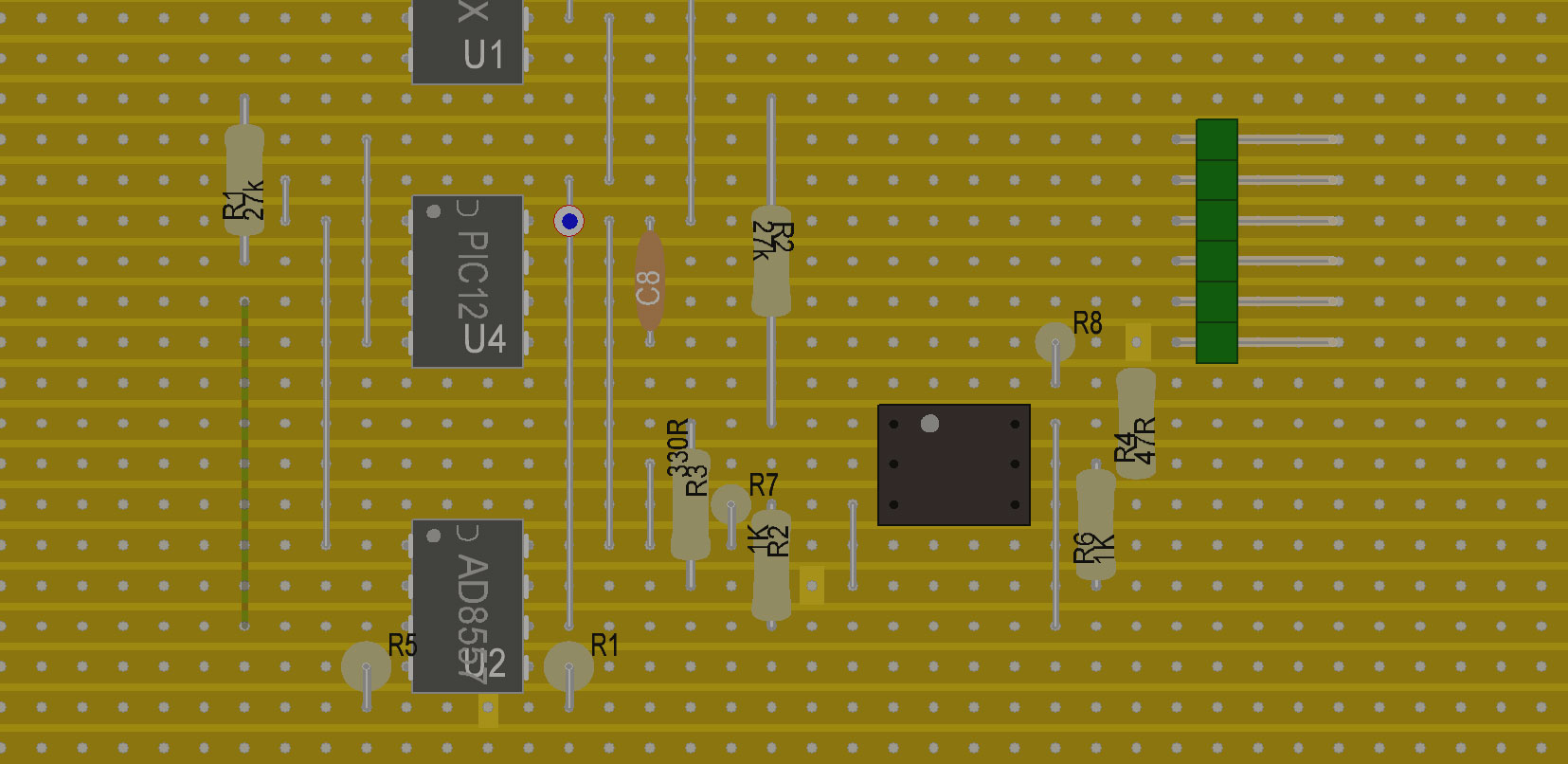

CEL designed a prototype circuit around the Analog Devices AD8557 digitally programmable amplifier IC. This device can be programmed to adjust its gain and offset without the need for a physical potentiometer. To control this device and allow it to be adjusted easily, CEL developed software for a Microchip PIC which presented a simple command line interface that could be used via terminal software on any laptop.

The CEL software included a self-calibration facility, so the previously time consuming and fiddly process of adjusting out the zero offset was replaced by a single command taking just moments to execute.

The hardware was first prototyped on stripboard, allowing it to be debugged and demonstrated before committing to a PCB. Finally the board was laid out and sent off for manufacture, with the final design being just 18x25mm.

As well as all the CAD data and source code, Reventec was provided with full documentation describing how the board works, how to connect it up, and how to adjust the gain and offset for any given application using the serial interface.

In this case a clear understanding of the needs of the application resulted in a simple, inexpensive PCB which was quicker to assemble into a finished sensor than an off-the-shelf board, as well as being more robust, accurate and versatile.

01252 511577

01252 511577