Over Heating

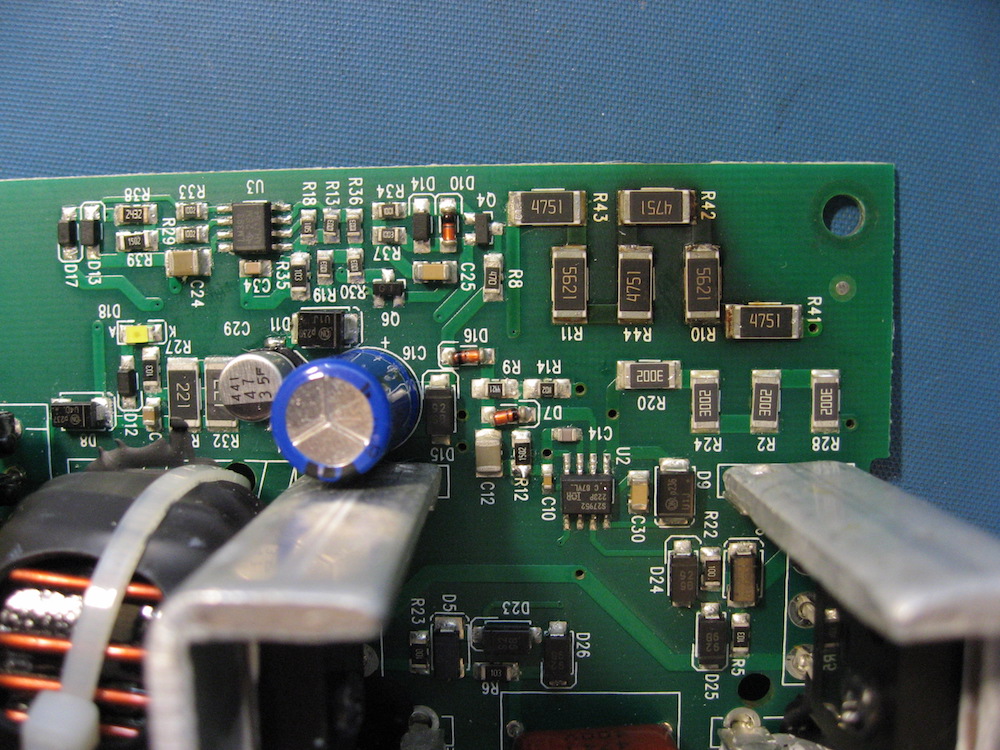

Sometimes no special equipment is needed in order to see something is getting hot. On this PCB, despite a nearby cooling fan, these parts have been running so hot the PCB is blackened, and although it’s not visible to the naked eye, one has a thermally induced stress crack. In this case the heat is an inherent feature of the design, but it’s been poorly managed, with these small resistors running well over 100C for hours on end.

Thermal Stress

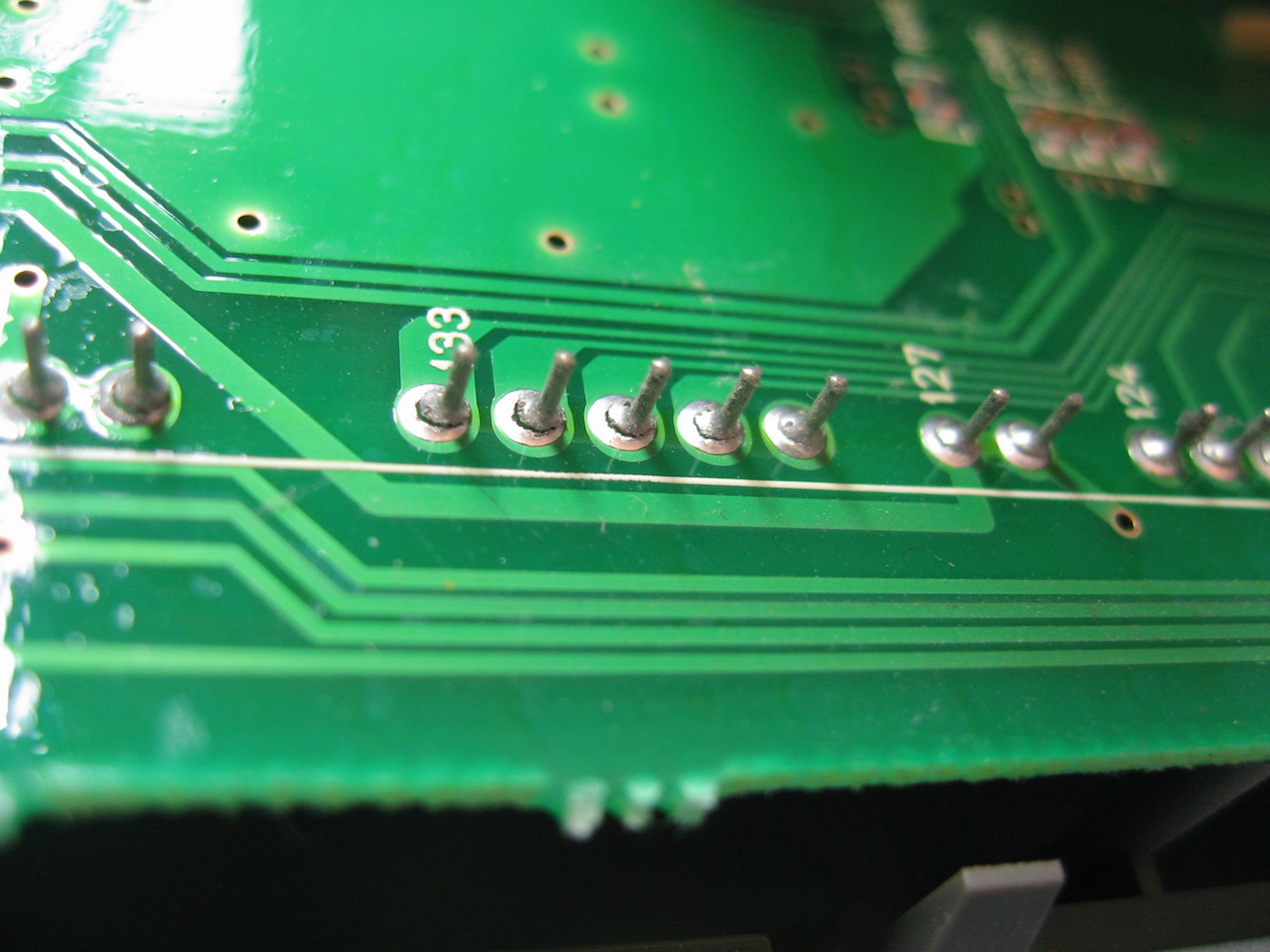

It’s not always simply running hot that’s the problem, but expansion and contraction due to thermal cycling. On this single sided PCB, repeated thermal stresses have caused a whole row of solder joints to fail – something which could have been avoided with minor design changes.

Thermal Imaging

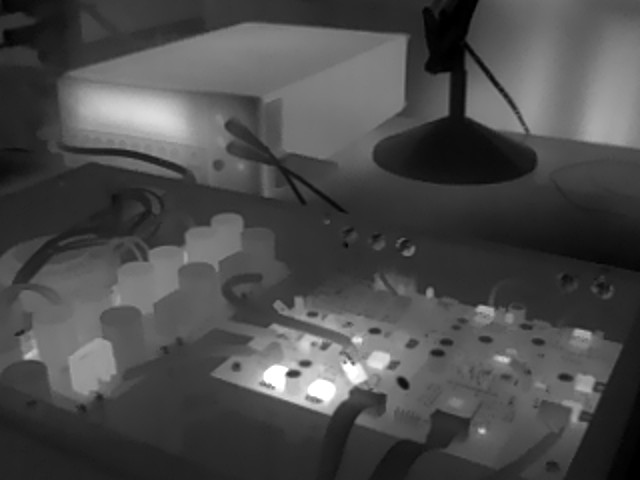

Thermal imaging can be a very powerful technique to quickly identify any parts which are getting hotter than expected. In some cases, faulty components literally light up on screen, meaning it takes just seconds to find the source of a problem which would otherwise require hours of careful, methodical probing to locate.

It’s also a quick way to check an entire board and confirm that *no* components are getting too hot; a valuable, confidence building step when bringing up a new design for the first time, or a way to rule out any number of common problems on a product which is believed to be faulty.

In this example, a piece of audio equipment has a few parts that are running warm, but no more so than they’re designed to do. This particular unit is working just fine.

Radio Interference

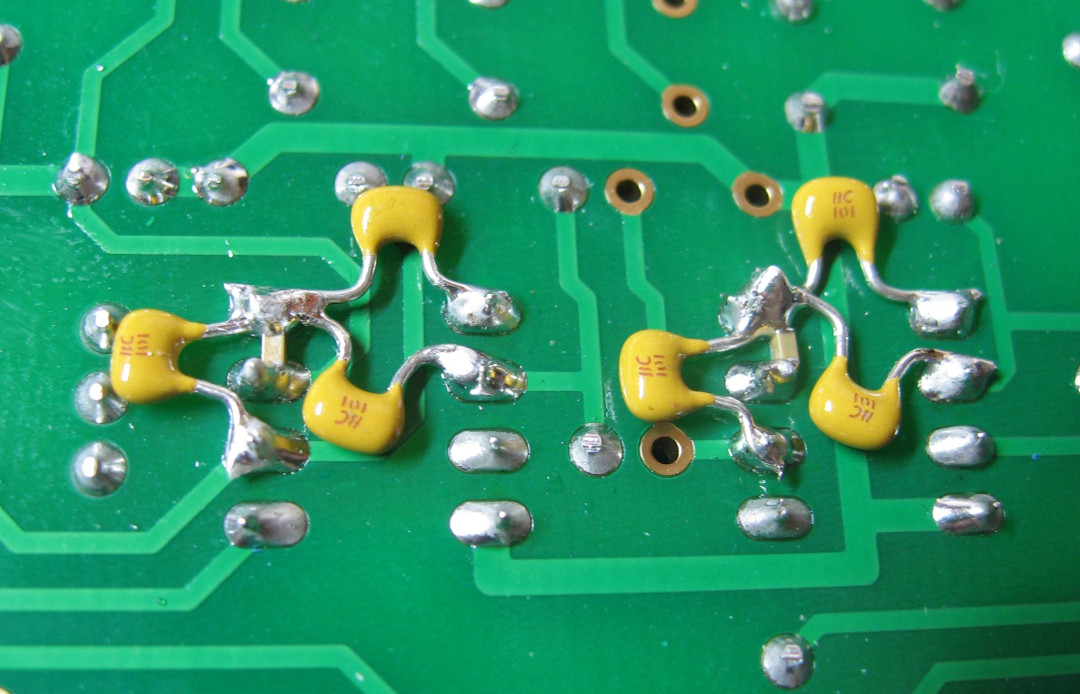

Sometimes a product works fine on the bench, but fails when exposed to unexpected influences from the outside world. Here, an audio amplifier was found to pick up interference from radio equipment used by emergency services. CEL is well used to dealing with EMC problems, and in this case a handful of capacitors worked wonders.

01252 511577

01252 511577